Factory Supply Q195 Q235 Q345 Round Tube Steel Round Pipe

Steel pipes are divided into seamless steel pipes and welded steel pipes. The production process of seamless steel pipe is to Pierce the solid tube billet or steel ingot into the hollow tube, and then roll it into the desired size of steel pipe. The different perforation and rolling methods used constitute different methods for producing seamless steel pipes. The production process of welded steel pipe is to bend the tube billet (steel plate or strip) into a tube shape, and then weld the gap to become a steel pipe. Because the molding and welding methods used are different, they constitute different methods for producing welded steel pipes.

Seamless steel pipe is mainly produced by hot rolling method. The extrusion method is mainly used to produce low-plastic high-alloy steel pipes or special-shaped steel pipes and composite gold pipes that are difficult to perforate. Cold rolling and cold drawing methods can continuously process hot rolled pipes into small diameter and thin-walled steel pipes. The welding steel pipe process is simple, the production efficiency is high, the cost is low, and the product variety is expanding.

1.Stainless steel industrial pipe, also known as schedule pipe, is a type of piping used in various industrial applications that require high strength, durability, and corrosion resistance.

2.Round pipes are often used to make road facilities such as guardrails and sign poles. Its strength and durability guarantee the robustness and durability of road facilities.

3.In addition, the round pipe can also be used to make traffic signal poles, street lamp poles and other equipment support components. The plasticity of the round tube makes it suitable for making support members of various shapes to meet the needs of different scenarios.

Product Parameters

| Product name | Round pipe |

| Technical standard | Cold Rolled /Hot Rolled |

| Thickness | 0.6 - 30 mm or customized |

| Length | 6m,12m or customized |

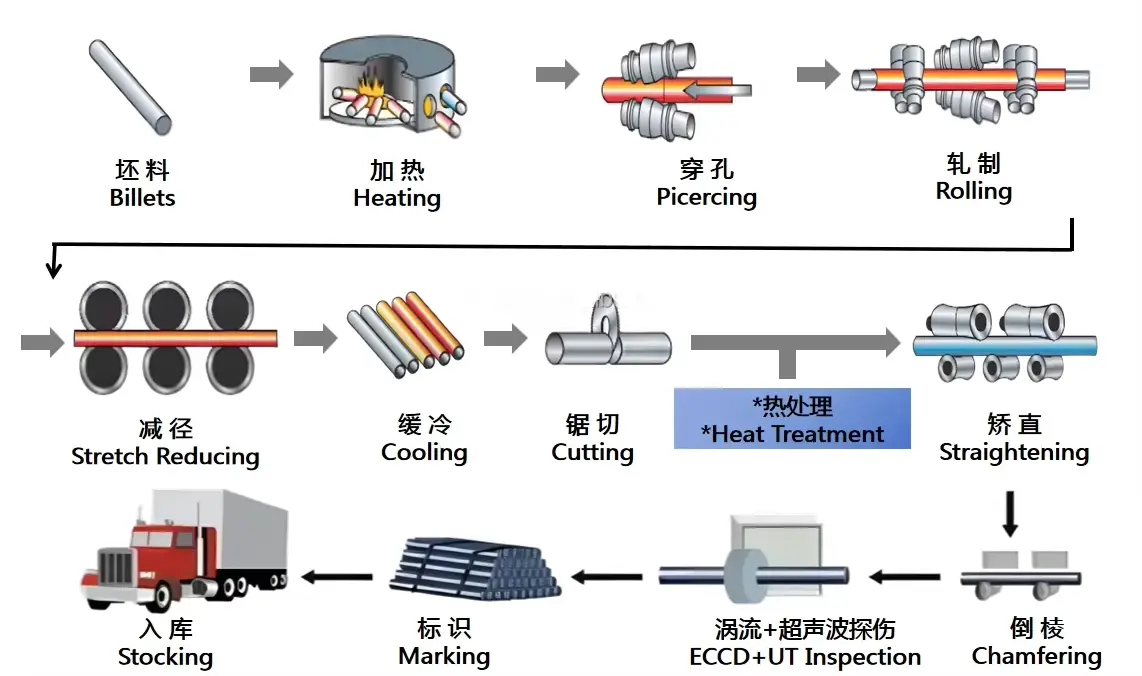

Production Flow Chart

Project Case

Pack And Ship

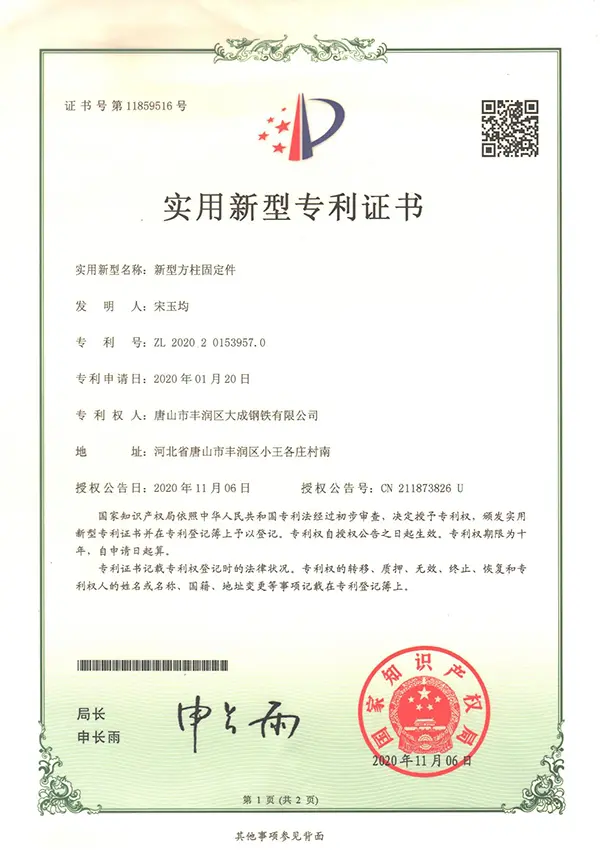

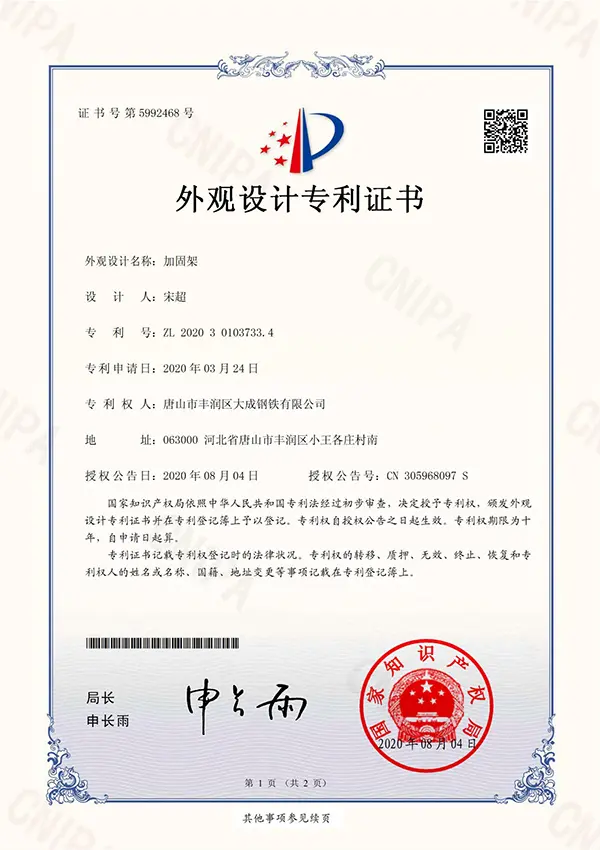

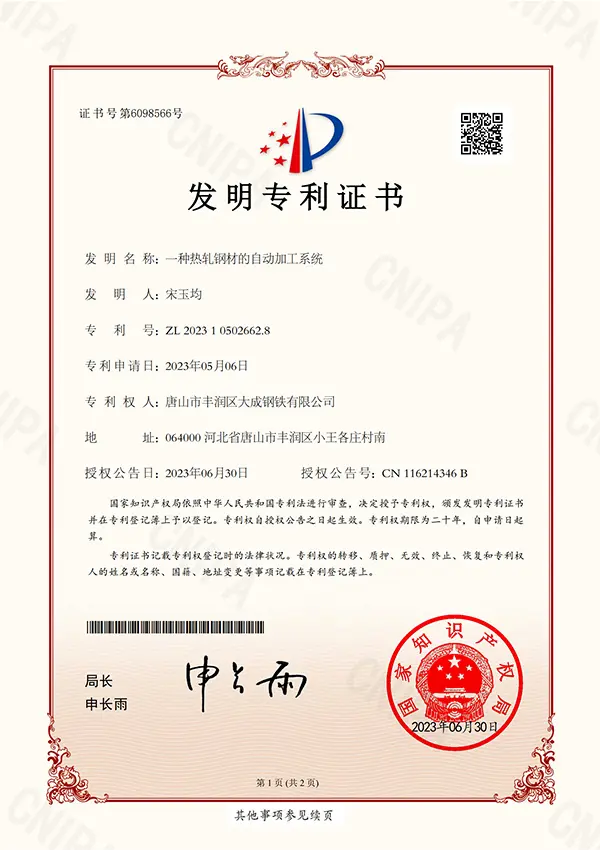

Certificate

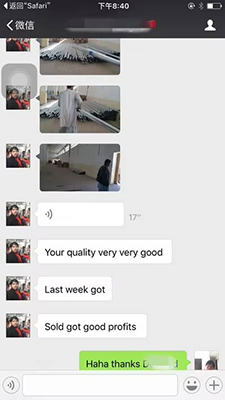

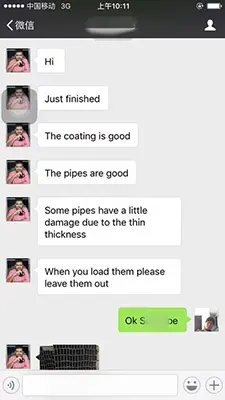

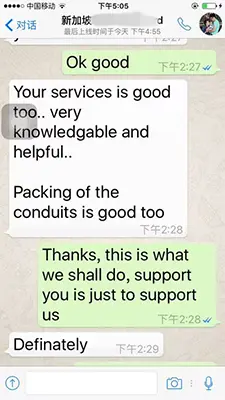

Customer Praise

Plant And Equipment

FAQ

Q: Are you manufacturer or trade company?

A: We are professional manufacturer of thermal insulation material, more than 10Years.

Q: Do you accept sample order?

A: Sample order is acceptable. We can offer free sample, sample can be sent within 1~3 days after freight payment confirmed.

Q: Does your company and products has any certification to ensure quality?

A: We are in compliance with ISO14001, ISO9001, OHSAS18001 certificate etc. Our products have excellent chemical, physical features and stability.

Q: What services can provide?

A: * Any inquires will be replied within 0-1 hours.

* We are professional manufacturer and trade company. Welcome to visit our company and factories at any time!

* Any your idea on the packing we can help you to design and put into production. Customized product is available.

* High quality, reasonable and competitive price, fast lead time.

* All products will have been strictly quality checked in house before packing.

* All products will be well packed before shipping. Sample order prepared, about 3-10 days for delivery productions.

Q: What is inspection process for Rubber Foam?

A: Raw Material Inspection - Production Process Inspection - Factory Inspection - Parallel Sample Tracking System.

Q: What’s the delivery time of 1x40HQ container loading order?

A: Within 3-20 days after receipt of prepayment.