What are the types and uses of flat bars?

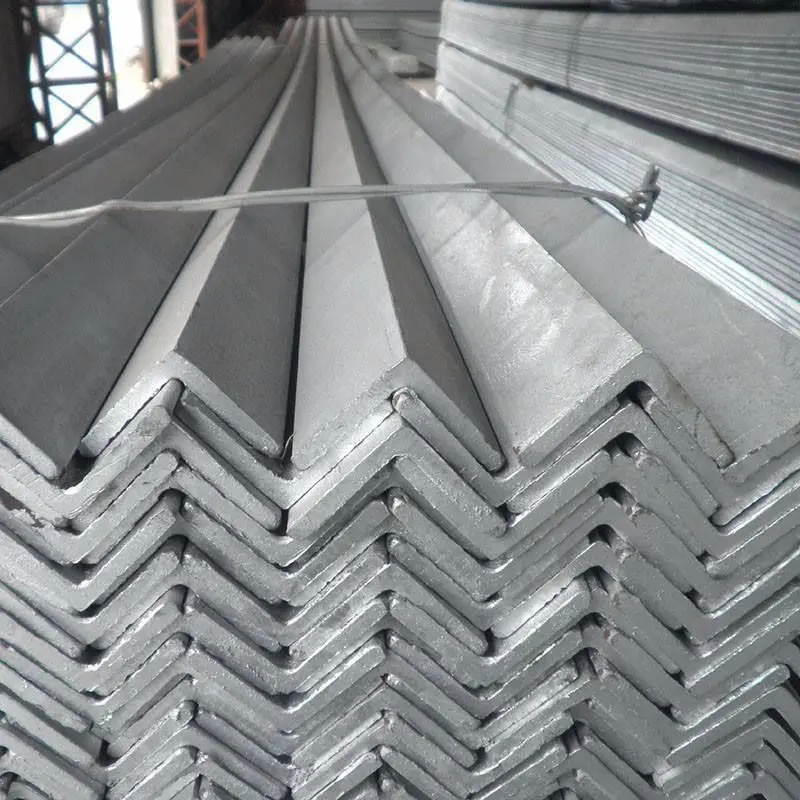

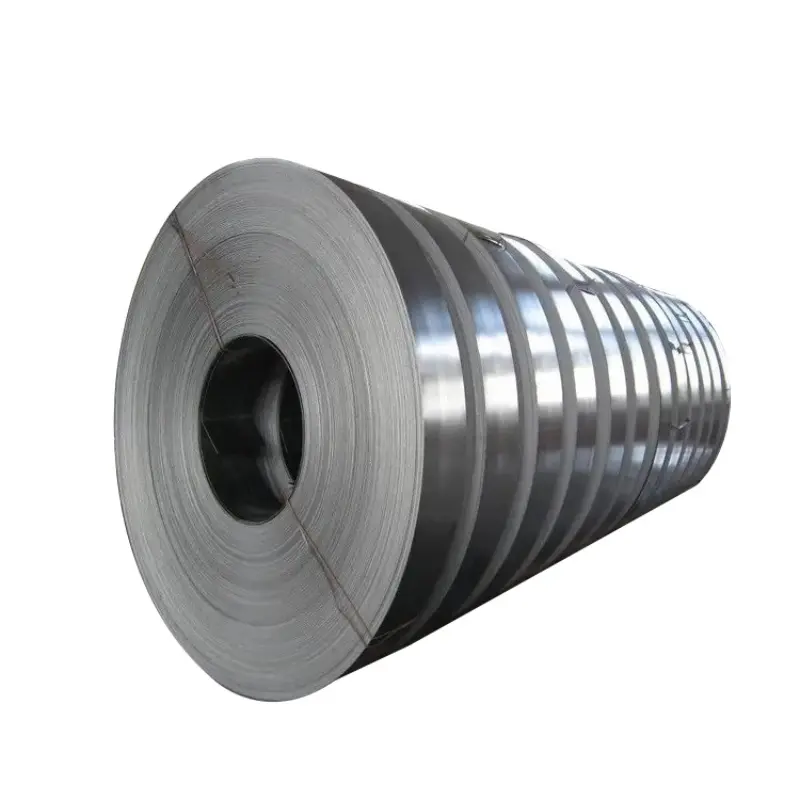

Flat steelrefers to Steel with a width of 12-300mm, a thickness of 3-60mm, a rectangular cross-section and a slight blunt edge.Flat bars can be finished steel, or they can be used as blanks for welded pipes and thin slabs for stacked sheets. Main uses: Flat Steel can be used as a finished material to make hoop iron, tools and mechanical parts, and is used as a frame structural part and escalator in construction.

According to the forging process, flat steel can be divided into: hot-rolled flat steel and forged flat steel

1. Hot-rolled flat steel

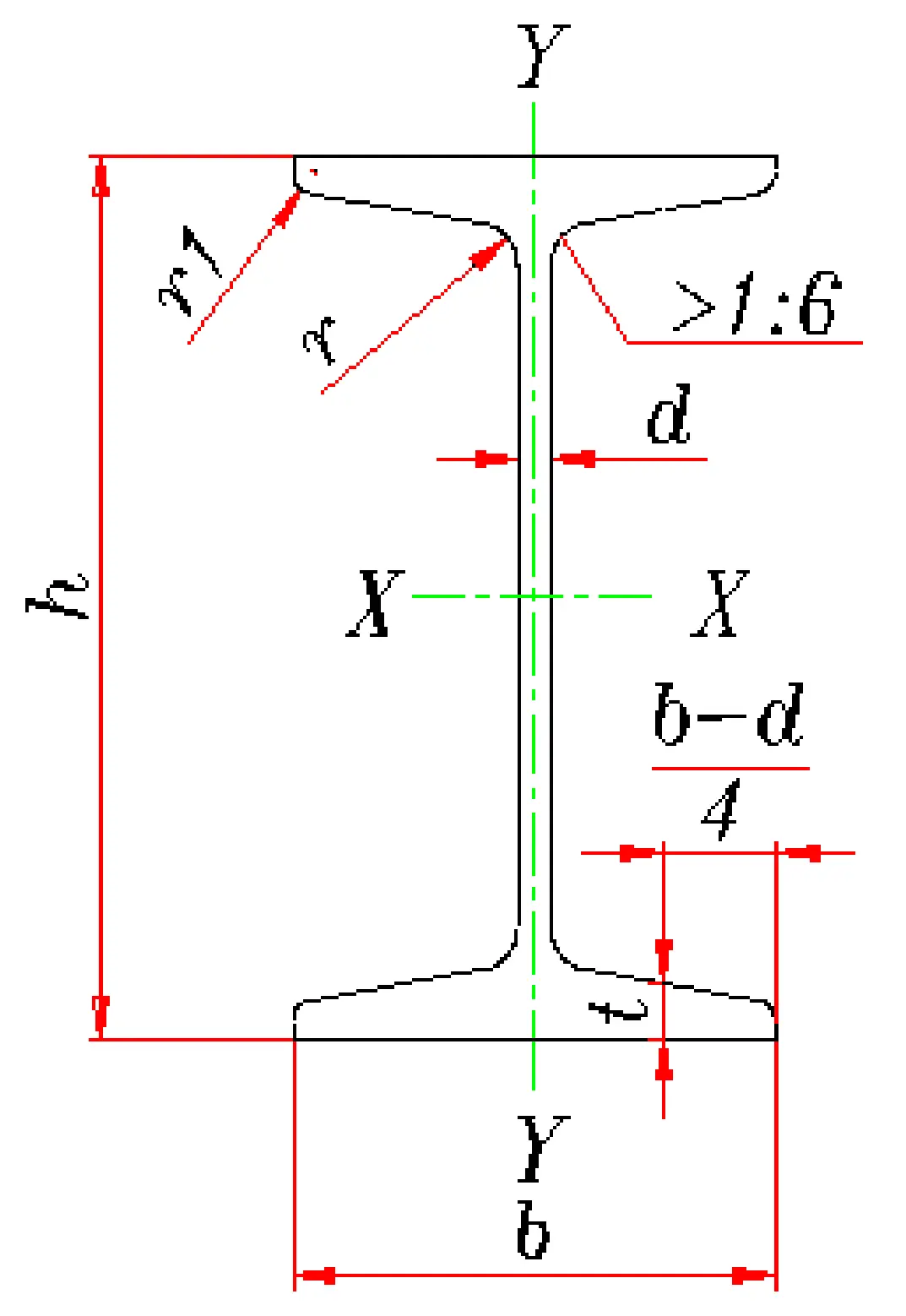

Hot-rolled flat steel is a long-rolled steel with a rectangular cross-section for general use. Its specifications are expressed in millimeters of thickness * width, and flat bars can be finished steel, which are used for components, ladders, bridges and fences. Flat bars can also be used for welding steel and billets and slabs of stacked sheets. (Material: Q215, Q235), the implementation standard: GB704-1988 instead of GB704-83, this standard is applicable to the thickness of 3~60mm, the width of 10~200mm, the cross-section is rectangular for general purpose hot-rolled flat steel. Delivery Condition: Flat bars are delivered in straight strips. Measurement method: The flat steel with fixed length and door length is delivered according to the theoretical weight.

2. Forged flat steel

Forged flat steel is a long steel plate with a rectangular cross-section that has been forged. Forging unfairness can obtain forgings of a certain shape and size, and at the same time, it can significantly improve the casting structure of steel and increase the density of steel. It can change the distribution of fiber structure, remove anisotropy, improve the mechanical properties of metal, and improve the strength and toughness of steel; And it can process high-speed steels and high-alloy steels with low plasticity. Forged flat steel is mainly high-quality alloy steel, which is mainly used as springs, tools and important mechanical parts. The specifications of forged flat steel are expressed in millimeters of thickness * width, and the specifications are 20mm*40mm~160mm*300mm. Executive standard: GB/T16761-1

The main uses of flat steel are as follows:

In the field of mechanical engineering

Flat bars have a wide range of applications in the field of mechanical engineering. Due to its unique shape and excellent physical properties, flat bars are often used to manufacture various mechanical parts, such as bearings, gears, etc. Its strong bearing capacity and good wear resistance make the machinery more stable and reliable during operation.

Construction and bridge engineering

In construction and bridge engineering, flat steel also plays an important role. Flat steel is used to construct the supporting part of steel bridges, and its high strength and excellent toughness make the bridge more stable. In addition, in the construction field, flat steel is also often used to make doors, windows, guardrails and other components.

Railway and rolling stock manufacturing

In the railway and rolling stock manufacturing industry, flat steel is mainly used in the manufacture of structural parts for tracks and vehicles. The compressive and wear-resistant properties of flat steel make it an ideal material to effectively ensure the stable operation of railways and vehicles.

Applications in other areas

In addition to the above-mentioned fields, flat bars are also widely used in other fields. For example, in the power industry, flat steel is used to make the support structure of power lines; In shipbuilding, flat bars are used in the construction of hull structures; In agriculture, flat steel is used to make agricultural tools, etc. Due to its high strength and good processing performance, flat steel has an irreplaceable role in various fields.

Advantages of flat bars

Flat bars are available in a variety of different thicknesses and widths, and the length is also optional. In this way, it can meet the needs of different users, and it can also be used instead of the middle plate, and it can be directly welded without cutting, etc., which has strong practicability and is also very convenient. Moreover, the finished surface is smooth and clean, ensuring secondary use in the later stage.

At the same time, the size of the flat steel is accurate, the straightness and the version are very good, and the finishing rolling process is adopted, which can automatically control different sizes, etc., and the processing can also meet our needs. Moreover, many regular manufacturers can provide customized processing services, which can also ensure the accuracy of the size of their products, the tolerance range is small, and the practicability is also guaranteed.

Email:manager@fsdsteel.com

Phone/Whatsapp:+86-18831507725