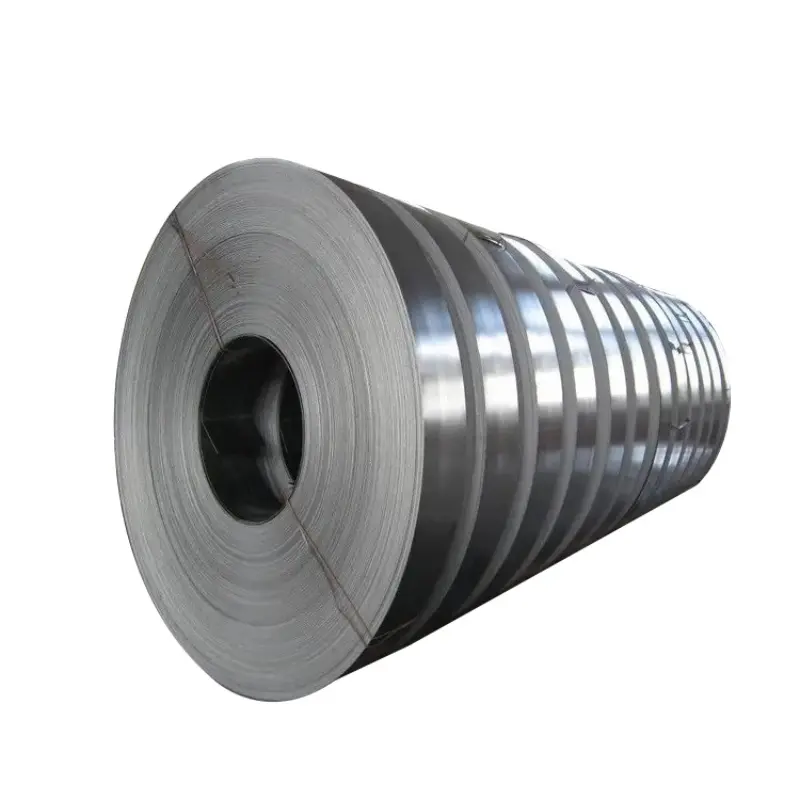

Understand the use of oil quenching steel wire

Oil-quenched steel wirerefers to the process of heating the Steel Wire to the austenitizing temperature and then rapidly cooling it with oil as the quenching medium to obtain a martensitic structure.

This process is usually combined with tempering treatment to improve the strength and toughness of the steel wire, so that it has excellent elasticity, fatigue performance and thermal stability. It is widely used in the manufacture of automobile springs, valve springs, etc.

Process flow of oil-quenched steel wire:

1. Heating:

The steel wire drawn to the specified size is heated to the austenitizing temperature in a continuous furnace.

2. Quenching:

The heated steel wire is placed in an oil tank for rapid cooling to change the structure of the steel wire and form martensite.

3. Tempering:

In order to improve the strength and toughness of the steel wire, tempering treatment is usually performed to give the steel wire a tempered martensitic structure.

Characteristics of oil-quenched steel wire:

High strength and high toughness coexist: The steel wire after oil quenching has high strength and good toughness and can withstand large external forces.

Good elasticity and fatigue resistance: The steel wire has strong elastic recovery ability, can effectively resist fatigue damage and extend service life.

Good dimensional accuracy and surface quality: Oil quenching treatment will not have a significant negative impact on the dimensional accuracy and surface quality of the steel wire.

Good anti-relaxation performance: Compared with cold-drawn steel wire, oil-quenched steel wire has better anti-relaxation performance.

High operating temperature: Oil-quenched steel wire can be used at higher temperatures, reaching 150-190°C.

Applications of oil-quenched steel wire:

Springs: automotive valve springs, suspension springs.

Others: various steel wire products that require high strength, high elasticity and high fatigue resistance.

Wide range of applications

Automotive industry: core materials for clutch springs and suspension springs to ensure driving safety;

Construction engineering: cables for cable-stayed bridges and steel wire for prestressed concrete to enhance structural stability;

Machinery manufacturing: transmission parts for industrial robots and steel wire ropes for mining machinery, which are wear-resistant and impact-resistant;

Daily necessities: high-end gardening tools, springs for medical devices and other precision parts.

Comparison: Oil-Tempered Wire vs. Cold-Drawn Wire

| Property | Oil-Tempered Wire | Cold-Drawn Wire |

|---|---|---|

| Strength | High | Relatively Low |

| Toughness | Good | Poor |

| Elasticity | Excellent | Fair |

| Fatigue Resistance | Outstanding | Poor |

| Thermal Stability | High | Low |

| Relaxation Resistance | Good | Poor |

| Operating Temp. | 150~190°C | ≤120°C |

| Microstructure | Uniform tempered martensite | Fibrous, highly anisotropic |