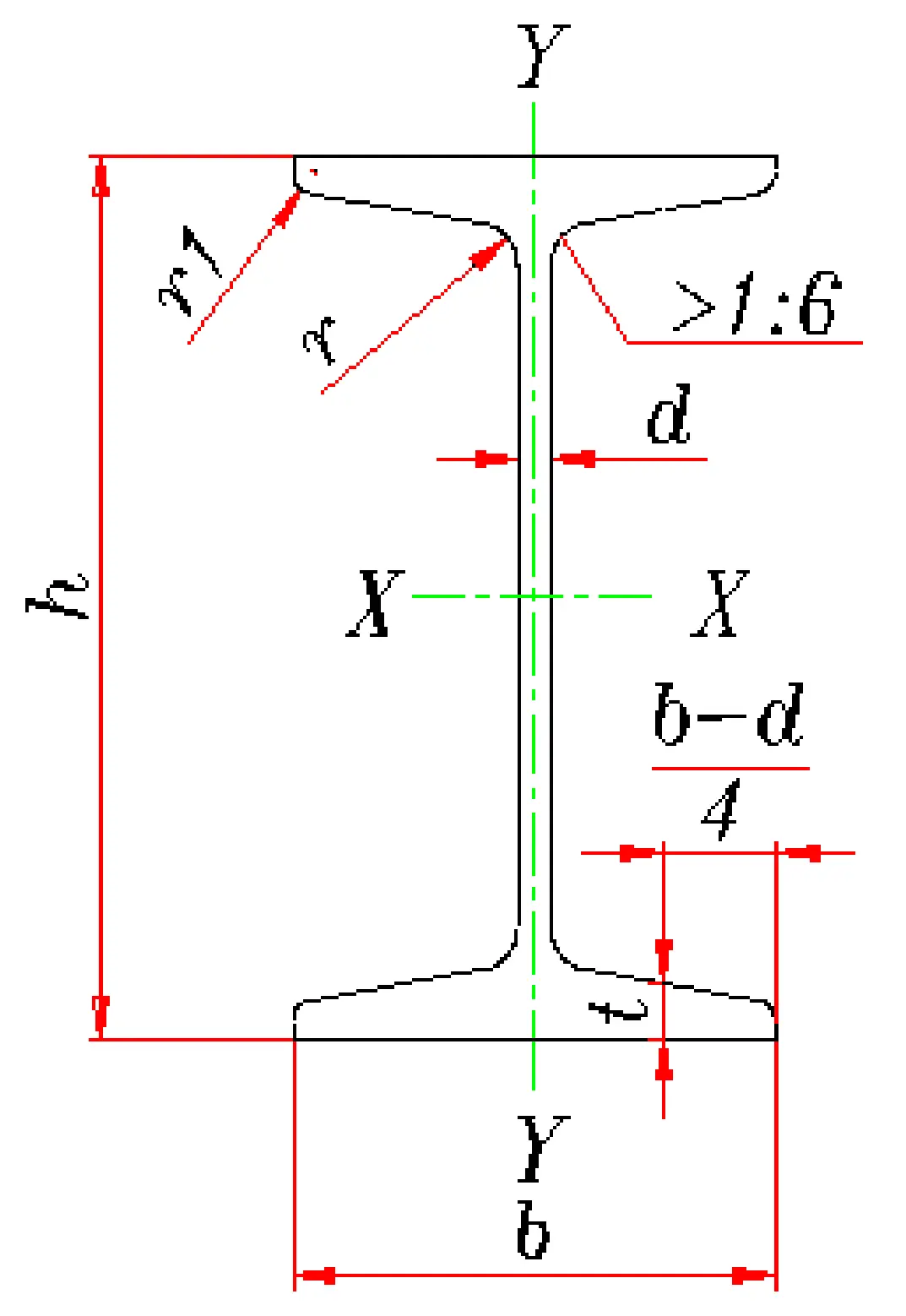

IPE/ IPEAA / IPEAAAA beam steel

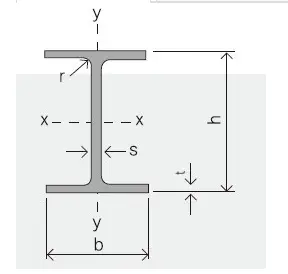

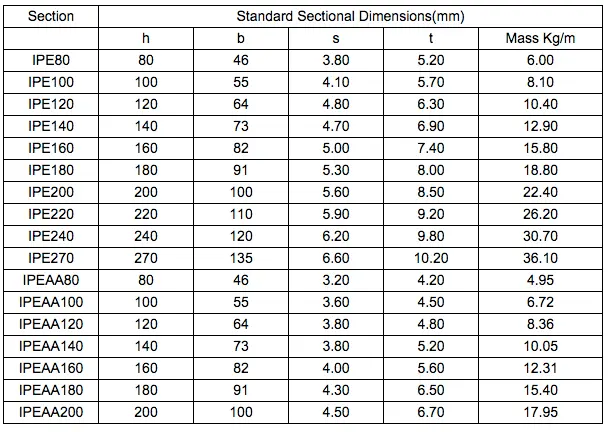

Specifications of IPE/IPEAA Beam Steel

Applications of IPE/IPEAA Beam Steel

IPE/IPEAA Beam Steel is extensively utilized in a variety of construction projects, including building structures, bridges, automotive frameworks, brackets, and mechanical systems. Its versatility and strength make it a preferred choice across multiple industries.

Packing & Delivery Terms for IPE/IPEAA Beam Steel

-

Packaging: IPE/IPEAA Beam Steel is securely bundled using Wire Rods.

-

Bundle Weight:

-

Maximum 3.5 metric tons (MT) for bulk vessel shipments.

-

Maximum 3 MT for container shipments.

-

-

Marking:

-

Color Marking: For bulk vessel deliveries, color markings are applied to both ends of the bundles for easy identification at the destination port.

-

Tag Marking: Each bundle includes a tag with essential details such as the supplier’s logo, product name, origin (Made in China), shipping marks, and any additional customer-requested information.

-

For container shipments, marking is optional but can be provided upon customer request.

-

-

Shipment Options: Available in both containerized and bulk cargo formats.

-

Delivery Time: All IPE/IPEAA Beam Steel will be delivered to the shipment port within 45 days after receiving the Letter of Credit (L/C) at sight or advance payment.

-

Payment Terms:

-

30% advance payment before production.

-

70% payment before shipment via T/T or L/C at sight.

-

Production Process of IPE/IPEAA Beams

The manufacturing process involves the following steps:

-

Material preparation (billet).

-

Heating.

-

Rough rolling.

-

Precision rolling.

-

Cooling.

-

Packaging.

-

Storage and transportation.

This streamlined production ensures high-quality IPE/IPEAA Beam Steel, meeting the demands of diverse industrial applications.