Flat Steel: A Versatile Material for Various Industries

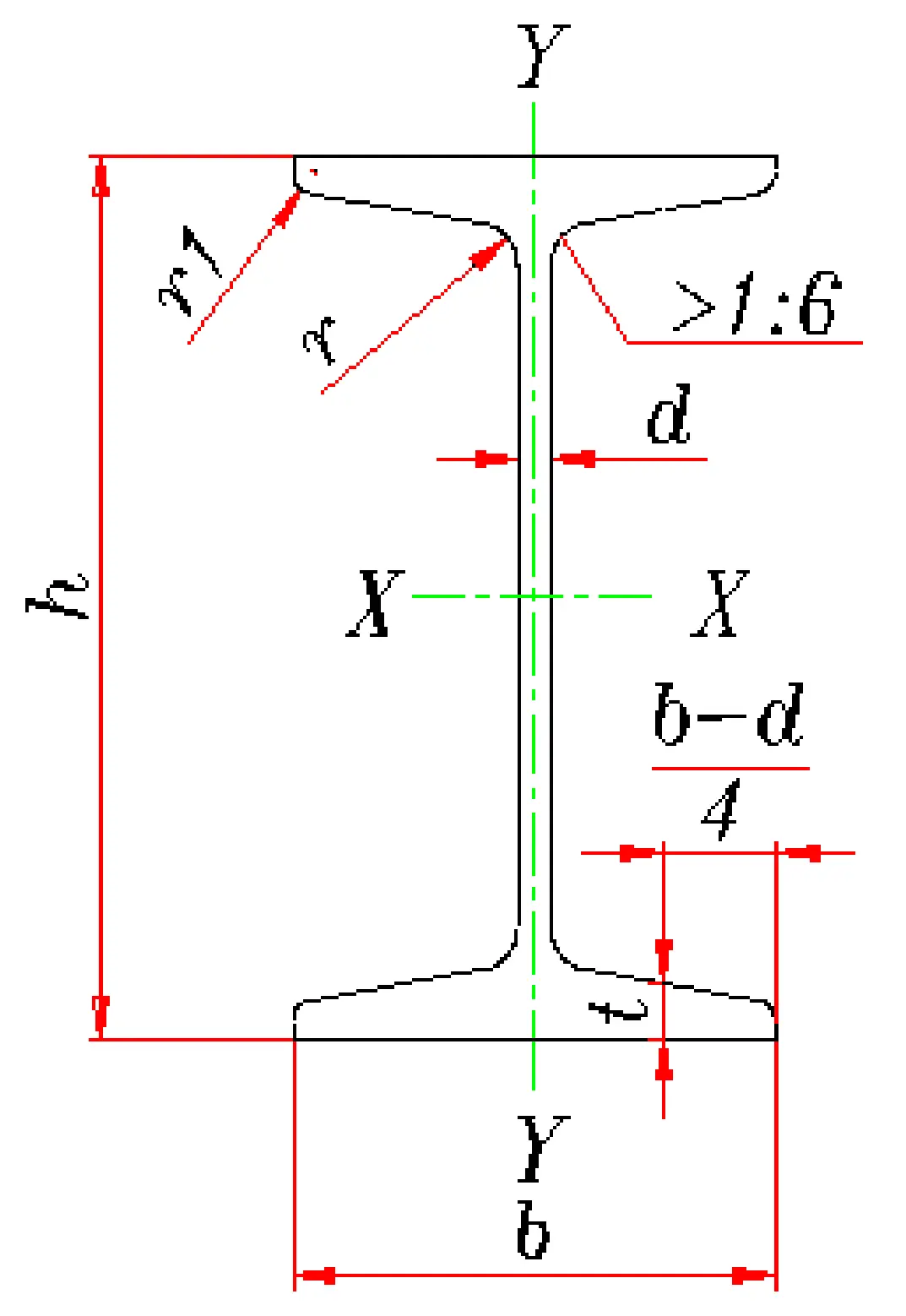

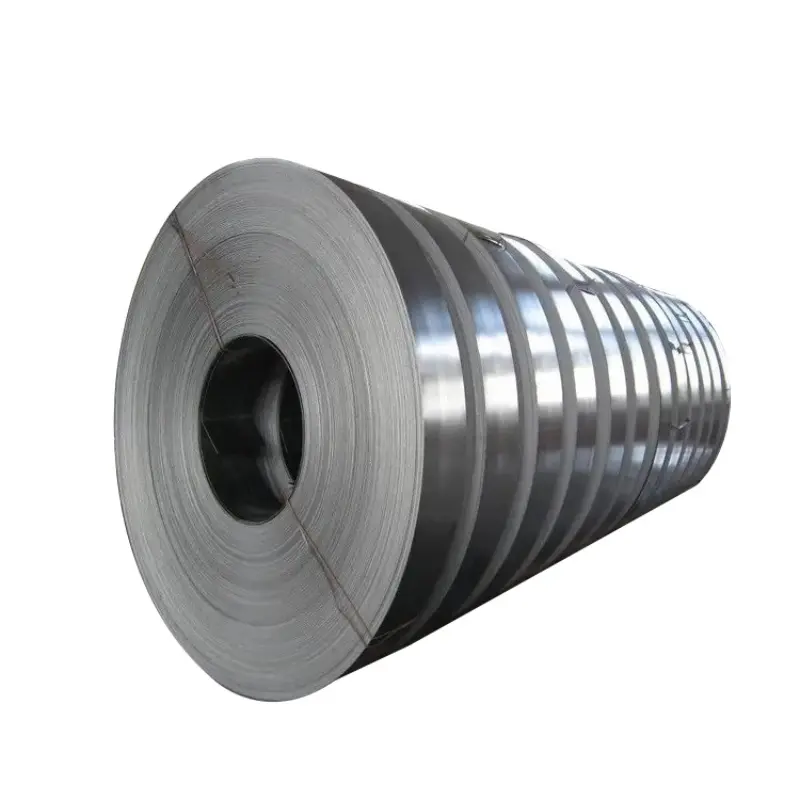

Flat steel, characterized by its rectangular cross-section with slightly rounded edges, typically ranges in width from 12-300mm and in thickness from 3-60mm. It serves as both a finished product and a raw material for Welded Pipes and thin plate billets. Widely used in manufacturing hoops, tools, machinery parts, and structural components in construction, flat steelis a crucial material in industries such as Steel structure manufacturing, machinery production, automotive, mining machinery, and lifting equipment.

Key Features and Advantages:

-

Specialized Product Specifications: Flat steel is available in thicknesses of 8-50mm, widths of 150-625mm, and lengths of 5-15m. Its dense range of specifications allows it to replace medium plates without the need for cutting, enabling direct welding and reducing processing time.

-

Smooth Surface Finish: The production process includes a secondary high-pressure water descaling step, ensuring a clean and smooth surface.

-

Precision Edges: Through two vertical rolling passes during finishing, Flat Steel achieves excellent edge straightness and clear angles, enhancing its edge surface quality.

-

Accurate Dimensions: The continuous rolling process, combined with automatic loop control, ensures high dimensional accuracy. Parameters such as tolerance range, three-point difference, and straightness surpass those of medium plates. Cold shearing further guarantees precise length cutting.

-

Compliance with National Standards: Flat steel is produced according to the YB/T4212-2010 standard, with materials such as Q345B and Q235B adhering to GB/T1591-94 and GB/T700-06 standards, respectively.

Benefits:

-

Improved Utilization: Flat steel is rolled with negative deviation but delivered by actual weight, increasing utilization by 1-5% compared to traditional steel plates.

-

Customizable Production: Flat steel can be produced to specific thicknesses, widths, and lengths, reducing the need for cutting and saving labor, material, and processing time. This customization minimizes raw material waste and enhances efficiency.

Applications:

Flat steel is extensively used in the manufacturing of steel structures, machinery, automotive components, mining equipment, and lifting machinery. It is one of the four major types of steel products, alongside plates, pipes, and wires. Based on cross-sectional shapes, steel products are categorized into simple sections (such as square, round, flat, and angle steel) and complex sections (such as I-beams, channels, and rails).

Production Process:

The precision flat steel production process involves leveling, finishing, straightening, and post-leveling. The finishing machine uses a series of leveling and straightening rollers to achieve the desired thickness, width, and straightness. This system includes a control box, finishing rollers, pre-leveling units, finishing units, and straightening units.

Automotive Spring Flat Steel:

Hot-rolled spring flat steel is primarily used in the production of leaf springs for automobiles, tractors, and railway vehicles. The process involves converter steelmaking, which offers several advantages:

-

High-Quality Output: Using molten iron as the raw material reduces harmful elements, ensuring superior flat steel quality.

-

Cost Efficiency: High yield rates and lower electricity consumption reduce production costs compared to electric furnace methods.

-

Simplified Process: Direct casting of molten steel into billets eliminates the need for billet opening, further cutting costs.

-

High Dimensional Accuracy: Continuous casting ensures high dimensional accuracy, meeting customer requirements for precise specifications.

Weight Calculation:

The weight of flat steel per meter can be calculated using the formula:

Weight (kg/m) = 0.00785 × thickness (mm) × width (mm)

Flat steel continues to play a vital role in various industries due to its versatility, precision, and cost-effectiveness, making it an indispensable material in modern manufacturing and construction.