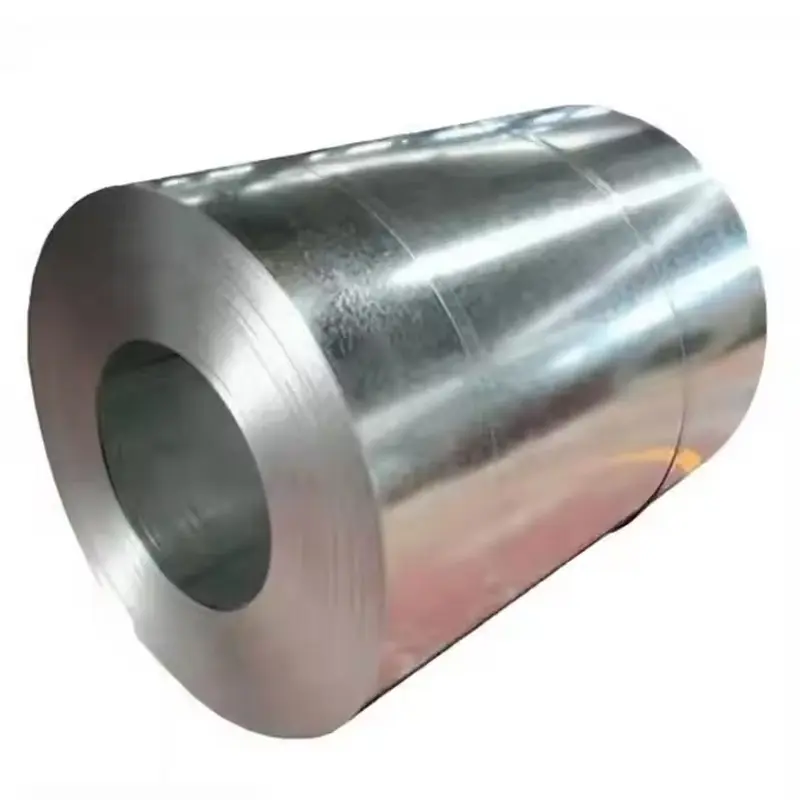

Hot Rolled Architectural Galvanized Steel Coil

Cold rolled sheet (English name: cold rolled sheet) is a product made of hot-rolled coil as raw material and rolled below the recrystallization temperature at room temperature. It is mostly used in automobile manufacturing, electrical products, etc. Cold rolling is rolling at a recrystallization temperature, but it is generally understood as rolling using materials that are rolled at room temperature.

1. Due to the lack of heating in the production process, there are no defects such as pitting and iron oxide scale that often occur in hot rolling, and the surface quality is good and the finish is high. Moreover, the dimensional accuracy of cold-rolled products is high, and the performance and structure of the products can meet some special use requirements, such as electromagnetic properties, deep drawing properties, etc.

2. Specifications: The minimum thickness is 0.2-4mm, the width is 600-2 000mm, and the length of the steel plate is 1 200-6 000mm.

3. Grade: Q195A-Q235A, Q195AF-Q235AF, Q295A(B)-Q345 A(B); SPCC、SPCD、SPCE、ST12-15; DC01-06

4. Performance: Mainly using low carbon steel grades, which require good cold bending and welding performance, as well as certain stamping performance.

Product Parameters

| Thickness | 0.12mm-1.2mm or 0.8mm/0.6mm/0.5mm/0.3mm/0.2mm or as requirements |

| Width | 600mm-1500mm or 914mm/1000mm/1200mm/1219mm/1220mm or as requirements |

| Surface Color | RAL/Printed/Matte/Wrinkled/Embossed/Nano |

| Painting Coating | Top: 10 to 35 um (5 um + 12-20 um) Back: 7 +/- 2 um |

| Coating Types | PE/PVDF/HDP/SMP |

| Coil Weight | 3 Tons -8 Tons |

| Coil ID | 508mm/610mm |

This is a paragraph