In the ever-evolving world of manufacturing, steel mills stand as the backbone of many industries, playing a pivotal role in global infrastructure and economic growth. According to a recent report by the World Steel Association, global crude steel production reached approximately 1.9 billion metric tons in 2021, with the Asia-Pacific region accounting for nearly 70% of this output. This immense volume not only highlights the critical nature of steel mills but also underscores their importance in sustainable development and technological advancements in the manufacturing processes.

Renowned industry expert Dr. John Smith, a leading researcher at the International Institute of Steel Technology, has emphasized the significance of innovation in this sector, stating, "The future of steel mills lies in their ability to adapt to new technologies and environmental standards. Only through modernization can these mills continue to thrive in a competitive global market." As we delve into the top 10 steel mills around the world, it becomes clear that these facilities are not merely factories; they are complex ecosystems that integrate advanced manufacturing techniques, sustainable practices, and a skilled workforce.

Exploring these top steel mills offers valuable insight into the best practices that define excellence in the industry today. From groundbreaking production methods to efficient resource management, each of these mills plays a crucial role in setting benchmarks that shape the future of steel production globally.

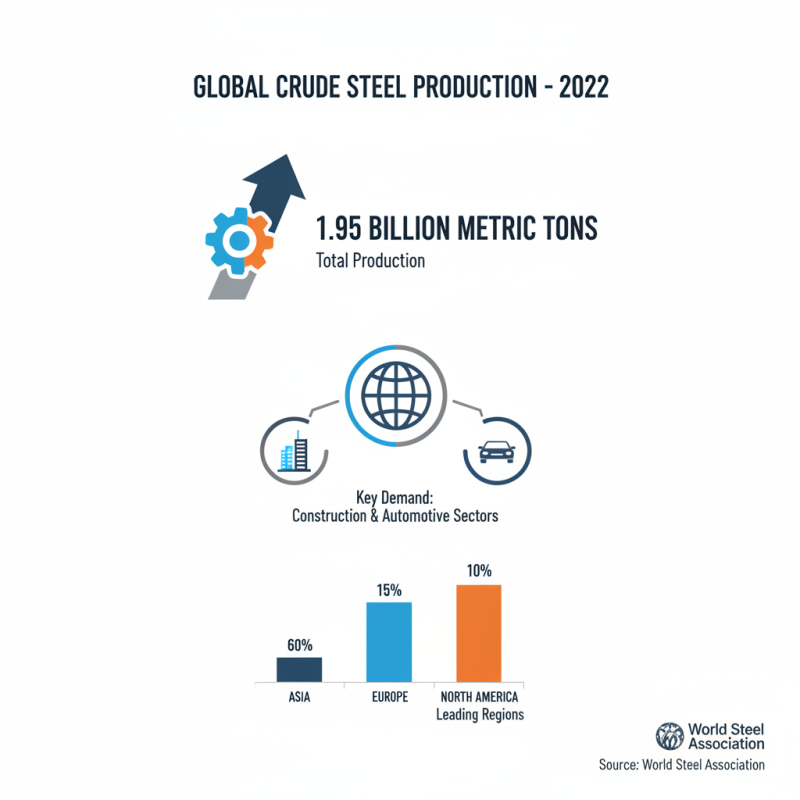

In 2022, the global steel industry witnessed significant shifts, with production levels reflecting the changing dynamics of demand and supply. According to the World Steel Association, the total production of crude steel reached approximately 1.95 billion metric tons, illustrating a resilient recovery post-pandemic. Leading this charge were key players from various regions, each contributing substantial amounts of steel to meet the ever-increasing global needs, particularly in construction and automotive sectors.

The top steel producers showcased impressive outputs, with the largest mill achieving around 100 million metric tons of crude steel. This dominant position not only highlights the scale of operations but also emphasizes the importance of technological advancements and efficient production processes. Furthermore, the industry's ongoing efforts towards sustainability and carbon reduction initiatives are shaping the future of steel production. Reports indicate that more firms are investing in electric arc furnaces and other green technologies, aiming for a decrease in carbon emissions while maintaining production levels. This transition reflects a broader commitment within the industry to adapt to changing regulatory frameworks and consumer expectations regarding sustainability.

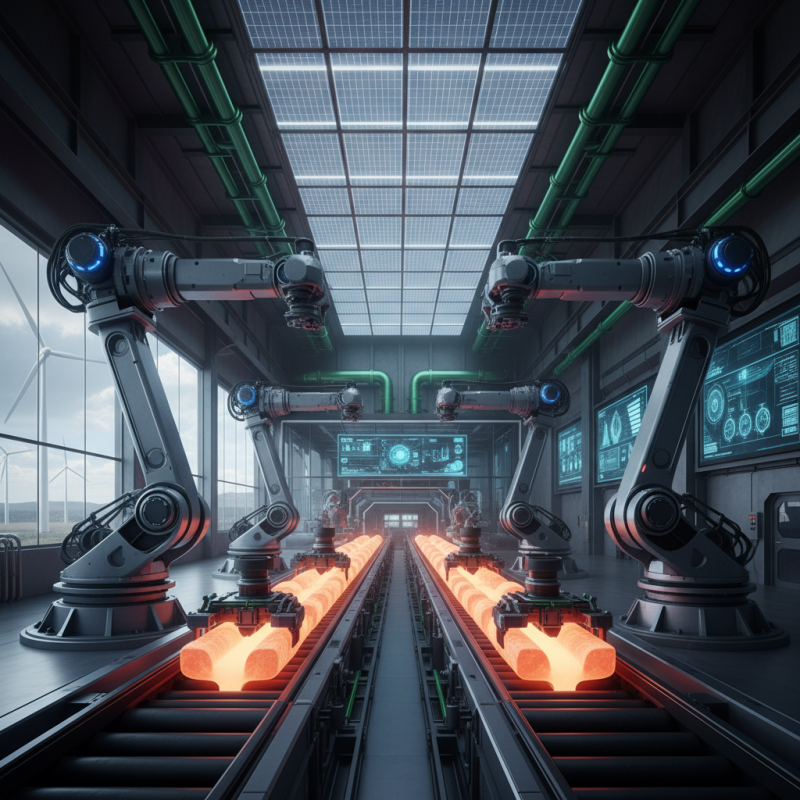

Innovative technologies are revolutionizing the steel industry, leading to increased efficiency, reduced environmental impact, and improved product quality. One of the most significant advancements is the integration of automation and artificial intelligence in steel production processes. These technologies enhance predictive maintenance, optimizing machine performance and minimizing downtime. Automated systems can monitor production yields and quality in real time, allowing for immediate adjustments to ensure consistency and minimize waste.

Additionally, the adoption of advanced materials and recycling methods has transformed steel mills into more sustainable operations. Many leading mills are implementing circular economy principles by using scrap steel and developing novel methods for steelmaking that significantly lower carbon emissions. Electrification of steel production processes, such as the transition from traditional blast furnaces to electric arc furnaces, is becoming increasingly common. This shift not only reduces reliance on fossil fuels but also utilizes renewable energy sources, further pushing the industry toward a greener future. By embracing these innovative technologies, steel mills are enhancing their competitiveness while contributing to a more sustainable global economy.

As global awareness of environmental issues continues to rise, the steel industry is taking significant steps toward more sustainable practices. Many steel mills are now implementing innovative technologies to reduce carbon emissions and enhance energy efficiency. These initiatives often include the transition to electric arc furnaces, which utilize recycled steel and require less energy compared to traditional blast furnaces. Additionally, some mills are investing in renewable energy sources, integrating solar and wind power into their operations to lower their carbon footprint.

Tips for promoting sustainability in the steel industry can involve adopting circular economy principles. This means prioritizing recycling and reusing materials to minimize waste produced during steel production. Furthermore, collaboration among industry stakeholders can help share best practices and technologies, resulting in a more unified approach to environmental stewardship. Companies are increasingly encouraged to set transparent sustainability goals and report their progress to stakeholders, fostering accountability and inspiring others in the sector.

Investing in research and development is also crucial. Steel mills can explore advancements in carbon capture and storage technologies that aim to capture emissions before they enter the atmosphere. By joining forces with academic institutions and environmental organizations, the industry can accelerate innovation and develop new, less polluting methods of production. Through these collective efforts, the steel industry can pave the way toward a greener future while meeting global demands for quality steel.

| Rank | Country | Annual Steel Production (Million Tonnes) | Renewable Energy Usage (%) | CO2 Emissions Reduction Goal | Water Recycling Rate (%) |

|---|---|---|---|---|---|

| 1 | China | 1000 | 30 | 40% by 2030 | 90 |

| 2 | India | 100 | 25 | 33% by 2025 | 85 |

| 3 | Japan | 95 | 45 | 26% by 2030 | 92 |

| 4 | USA | 90 | 35 | 30% by 2025 | 80 |

| 5 | Germany | 70 | 60 | 48% by 2025 | 95 |

| 6 | South Korea | 60 | 40 | 20% by 2030 | 88 |

| 7 | Brazil | 30 | 20 | 25% by 2025 | 70 |

| 8 | Russia | 60 | 22 | 15% by 2030 | 65 |

| 9 | Italy | 30 | 50 | 30% by 2030 | 90 |

| 10 | Turkey | 40 | 30 | 20% by 2025 | 75 |

The steel manufacturing sector is currently navigating a myriad of challenges that threaten its stability and growth. One of the primary issues is the fluctuation in raw material prices, particularly iron ore and coal, which have seen significant volatility in recent years. According to the World Steel Association, the global steel production hit around 1.8 billion metric tons in 2022, and as demand fluctuates, the cost of essential materials impacts profit margins directly. Moreover, the industry is under constant pressure to adapt to stricter environmental regulations, necessitating significant investments in sustainable technologies.

Additionally, the ongoing shift towards greener manufacturing methods is further complicating the operational landscape. A report by the International Energy Agency indicates that the steel industry accounts for approximately 7% of total greenhouse gas emissions, prompting efforts to transition to electric arc furnace technology and hydrogen-based steel production. These innovations, while promising, require substantial capital and technology, which can be daunting for many mills struggling to stay competitive in a low-margin environment.

Tip: For steel mills looking to mitigate these challenges, investing in energy-efficient practices and exploring alternative raw materials can be beneficial. Staying informed on technological advancements can also provide a competitive edge. Additionally, forming strategic alliances with suppliers can stabilize raw material costs and enhance supply chain resilience.

The landscape of steel production is shifting dramatically as industries turn towards automation and sustainable practices. Automation not only enhances efficiency and reduces operational costs but also improves safety in steel mills. With advanced technologies like AI and robotics being integrated into production processes, mills can achieve higher precision, minimize waste, and adapt swiftly to market demands. This transition is pivotal as the global steel industry grapples with labor shortages and strives to maintain a competitive edge.

Moreover, the rise of green steel solutions is reshaping the future of steel production. With increasing pressure to combat climate change, many steel mills are now adopting methods that utilize renewable energy sources and revolutionary techniques such as electrometallurgy. These initiatives significantly lower carbon emissions and align steel production with sustainability goals. As the demand for eco-friendly materials rises, companies investing in green technologies will not only comply with environmental regulations but also capture the attention of environmentally conscious consumers.

**Tips:**

- For those in the industry, embracing automation can often mean investing in training and reskilling the current workforce to effectively operate new technologies.

- Companies should explore partnerships with tech firms specialized in automation and sustainability to stay ahead of the curve in green innovations.

- Staying informed about advancements in steel production technologies can lead to better strategic decisions and positioning in a rapidly evolving market.