Material Steel plays a crucial role in both construction and manufacturing industries. According to a report by the American Iron and Steel Institute, steel is used in around 70% of all construction materials. This highlights its significance as a primary resource. Experts emphasize that this material’s strength and durability are unparalleled. Dr. John Steelman, a renowned material scientist, states, “Without Material Steel, modern infrastructure as we know it would not exist.”

The construction sector heavily relies on Material Steel for buildings and bridges. Its ability to withstand immense pressure and weight makes it invaluable. However, the environmental impact of steel production raises concerns. The industry is responsible for approximately 8% of global carbon dioxide emissions. This calls for reflection on sustainable practices and innovations. Companies are now exploring greener production methods to minimize their footprint.

In manufacturing, Material Steel is essential for machinery and tools. Its versatility allows for various applications across industries. Yet, with the demand for this material increasing, we must consider resource sustainability. As Material Steel continues to shape our surroundings, the challenges we face require thoughtful solutions. This balance is vital for future developments in both construction and manufacturing.

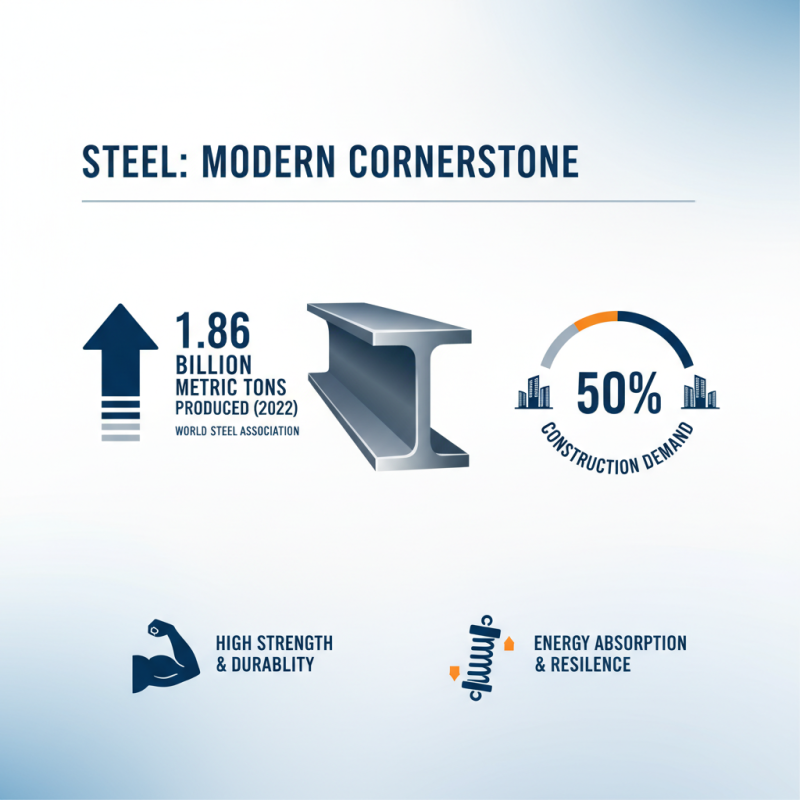

Steel is a cornerstone of modern construction and manufacturing. It boasts high strength, durability, and flexibility. According to a recent report by the World Steel Association, steel production reached 1.86 billion metric tons in 2022, making it one of the most widely used materials in the world. The construction industry alone accounted for approximately 50% of this demand. Steel’s ability to absorb energy makes it essential for creating resilient structures.

Building with steel allows for innovative designs. Skyscrapers and bridges rely on steel’s tensile strength. A report from the American Institute of Steel Construction reveals that steel-framed buildings can reduce construction time by up to 25%. Steel is also recyclable, promoting sustainable practices in manufacturing. However, steel production can be energy-intensive. The industry must continue to focus on reducing its carbon footprint.

**Tip:** Opt for recycled steel when possible. This choice significantly lowers environmental impact.

A drawback of steel is its vulnerability to corrosion. Proper coating and maintenance are crucial to enhance longevity. Investing in quality treatments can save costs in the long term. While steel has many advantages, challenges like rising production costs must be addressed. Embracing new technologies and methods is vital for the future of steel in construction and manufacturing.

**Tip:** Always conduct regular inspections on steel structures. This ensures safety and performance over time.

Steel is a remarkable material widely used in construction and manufacturing. Its strength is one of its most notable properties. Steel can bear heavy loads without breaking. This strength allows for the construction of skyscrapers and bridges. It reshapes our cities and infrastructures across the globe.

Another key property of steel is its flexibility. Steel can be molded into various shapes. This versatility means it can meet diverse needs. From beams in buildings to components in machinery, steel adapts well. However, challenges exist. The manufacturing process can produce waste and emissions. Not all steel is created equal, and quality can vary significantly.

Corrosion resistance is also critical. Certain steel types resist rust and wear better. This makes them suitable for harsh environments, like coastal areas. Yet, this resistance is not universal. Maintenance remains crucial for longevity. In summary, while steel's key properties offer numerous advantages, awareness of its limitations fosters better practices in construction and manufacturing.

Steel plays a vital role in construction and manufacturing sectors. Its strength and durability make it a preferred choice for various applications. In structural engineering, steel beams and columns provide essential support for buildings. According to a report by the World Steel Association, about 1.7 billion tons of steel were used in construction in 2020 alone. This is expected to increase as urbanization grows.

In the infrastructure sector, steel is indispensable. Bridges, highways, and rail systems heavily rely on this material. The American Institute of Steel Construction highlights that steel is recycling-friendly, with about 90% of it being reused in new products. While this is a positive aspect, the production process can be energy-intensive. This raises concerns about carbon emissions associated with steel manufacturing.

Steel is also significant in residential construction. It allows for innovative designs and more open floor plans. The National Association of Home Builders reports that steel framing is becoming more common in new homes. However, builders must consider costs versus benefits. The steel market can be volatile, affecting project budgets. Overall, the multifaceted applications of steel continue to shape the construction landscape.

| Application Sector | Type of Steel Used | Key Properties | Benefits |

|---|---|---|---|

| Residential Construction | Carbon Steel | High Strength, Durability | Cost-effective, Sustainable |

| Commercial Buildings | Stainless Steel | Corrosion Resistance, Aesthetic Appeal | Long Lifespan, Low Maintenance |

| Infrastructure | Structural Steel | High Load-Bearing Capacity | Safety, Versatility |

| Manufacturing | Alloy Steel | Enhanced Mechanical Properties | Improved Performance, Efficiency |

| Energy Sector | Tool Steel | Hardness, Wear Resistance | Durability, Precision |

Steel production has a significant environmental impact. The process involves high energy consumption and carbon emissions. Producing one ton of steel can emit over 1.8 tons of carbon dioxide. This contributes substantially to global warming. Moreover, mining for iron ore can lead to habitat destruction. Rivers and ecosystems are often affected by this mining.

Despite these issues, efforts are underway to enhance sustainability in steel manufacturing. Innovations like electric arc furnaces are gaining attention. These methods reduce emissions by using scrap steel instead of raw materials. Additionally, recycling steel is more efficient. It requires less energy compared to producing new steel. However, recycling rates are not yet satisfactory globally.

Many industries rely heavily on steel, making it difficult to shift entirely to sustainable practices. The demand for steel is growing. As cities develop, so does the need for materials. The challenge lies in balancing this demand with environmental responsibility. Stakeholders must rethink their approaches. Implementing greener technologies will take time and investment, but it is necessary for a sustainable future.

The use of steel in construction is evolving rapidly. As urbanization increases, demand for innovative materials grows. Steel offers significant strength-to-weight ratios, making it ideal for skyscrapers and bridges. In fact, research shows that by 2030, steel demand in construction could rise by 30%.

New manufacturing techniques are reshaping the industry. Advanced methods such as 3D printing and modular construction are emerging. These technologies allow for quicker assembly and lower waste. However, integrating these methods with traditional steel construction poses challenges. The balance of cost and sustainability remains a key concern.

Sustainable steel production is another important trend. The industry is pushing towards greener practices. By 2025, it is predicted that 50% of steel will be produced using electric arc furnace technology. While this reduces carbon emissions, the transition can be slow and fraught with hurdles. Ensuring quality during this shift requires careful oversight and innovation.