In the ever-evolving landscape of construction, selecting the right materials is crucial for the success and longevity of a project. One of the most essential materials in a builder's toolkit is the steel bar. Known for its strength and durability, steel bar serves as the backbone in various construction applications, from structural frameworks to reinforcing concrete. As we dive into 2023, understanding the different types of steel bars available and their specific properties has become more critical than ever, ensuring that projects not only meet safety standards but also deliver optimal performance.

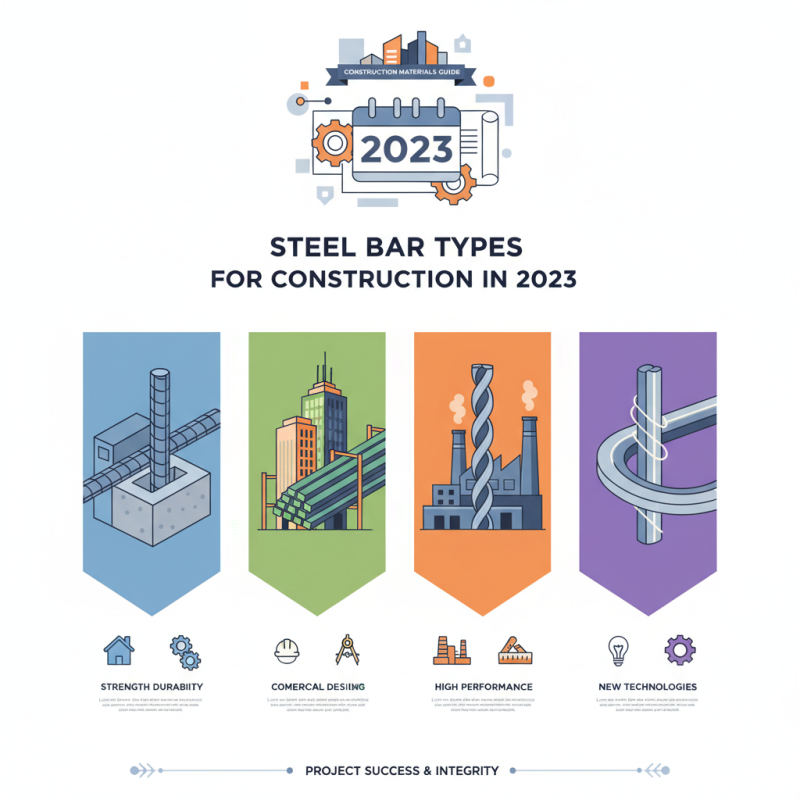

This guide will explore the best steel bar types suited for various construction projects in 2023, detailing their characteristics and benefits. Whether you are working on residential buildings, commercial structures, or industrial facilities, knowing which steel bar to choose can make all the difference in structural integrity and overall project success. As construction practices advance and new technologies emerge, staying informed about the latest innovations and recommendations in steel bar selection is essential for achieving your construction goals.

When it comes to construction projects, selecting the right type of steel bar is crucial for ensuring structural integrity and longevity. The primary types of steel bars used in construction include Mild Steel, High Tensile Steel, and Deformed Bars. Mild Steel bars, characterized by their ductility and ease of welding, are often utilized in structures where flexibility is desired, such as in residential buildings or small frameworks. Their lower yield strength makes them less suitable for heavy loads, but their versatility benefits many standard construction applications.

High Tensile Steel, on the other hand, is designed for maximum strength and is ideal for heavy-duty structures. It is commonly used in commercial buildings, bridges, and large-scale civil engineering projects. This type of steel bar can withstand higher stress and load without deforming, making it a preferred choice where safety and durability are paramount. Deformed Bars, recognized by their surface patterns, enhance bonding with concrete, thus improving load distribution. These bars are frequently used in reinforced concrete structures, ensuring that the components work together effectively under various loads and environmental conditions. Understanding these different types of steel bars and their specific applications allows construction professionals to make informed decisions tailored to the requirements of their projects.

This chart illustrates the various types of steel bars commonly used in construction projects and their respective applications and strengths as of 2023.

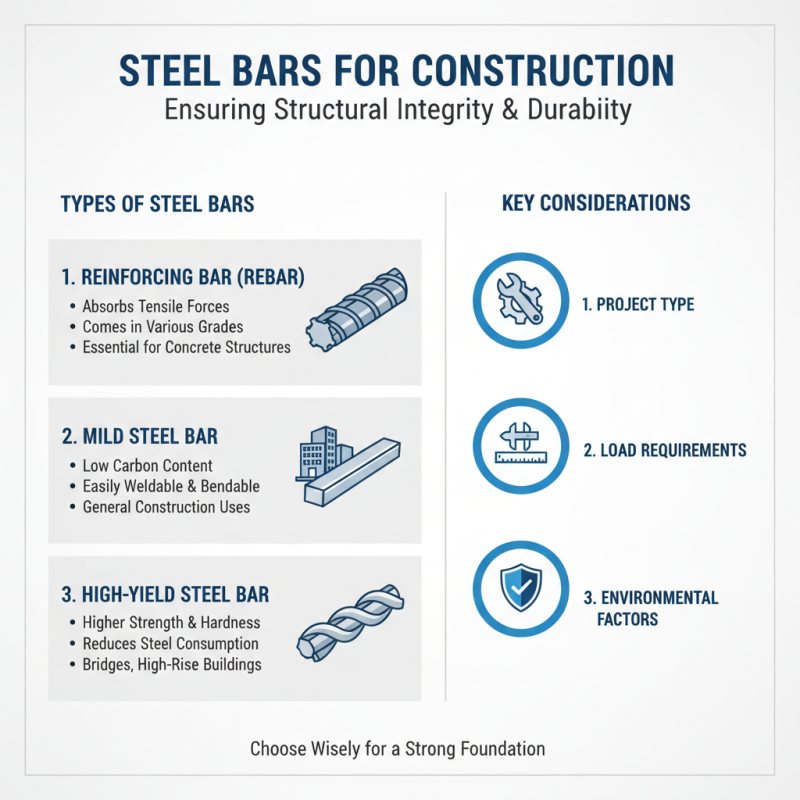

When it comes to construction projects, selecting the right type of steel bar is crucial for ensuring structural integrity and durability. Commonly used in a variety of applications, steel bars can be categorized into several types based on their specific characteristics and uses. One of the most prevalent types is the reinforcing bar, often referred to as rebar. Rebar is designed to absorb tensile forces, which typical concrete structures cannot withstand on their own. It comes in various grades, allowing engineers to choose the appropriate strength for different load-bearing requirements.

Another important category is the mild steel bar, which is known for its bendability and weldability. This type of bar is often used for general construction purposes and is a popular choice for creating frames, beams, and columns. Additionally, there are high-strength deformed bars that feature surface ridges to provide better mechanical anchoring within concrete. These are particularly favored in environments that demand high-performance materials, as they enhance the overall stability of the structure under stress or during seismic activities. Understanding these common types of steel bars enables construction professionals to make informed decisions that ultimately contribute to the success and longevity of their projects.

When selecting steel bars for construction projects, several key factors must be considered to ensure structural integrity and longevity. First, the purpose of the project plays a crucial role. For example, reinforcing bars (rebar) are commonly used in concrete applications to enhance tensile strength. According to the Global Construction Management Market report, the demand for rebar is projected to rise by 4.6% annually through 2025, driven by increased infrastructural investments worldwide. Understanding the specific requirements for tensile strength and ductility based on the project's demands is essential for choosing the right type of steel bar.

Another critical aspect is the environmental conditions the construction will face. Factors such as exposure to corrosive elements or extreme weather can significantly influence the choice of steel. Reports from the Steel Construction Institute highlight that high-performance steel bars, such as those treated with corrosion-resistant coatings, can prolong the lifespan of a structure by up to 35%. Furthermore, considering the ASTM standards for the quality and mechanical properties of steel bars can guide engineers in selecting the appropriate material that meets project specifications while adhering to safety regulations. Evaluating these factors thoroughly can lead to a more sustainable and cost-effective construction outcome.

Steel bars have become a crucial element in modern construction techniques, and their advantages are well-documented in various industry studies. A recent report by the American Institute of Steel Construction (AISC) highlights that steel bars offer exceptional tensile strength and ductility, crucial for structures that must withstand dynamic loads. This capacity for energy absorption makes steel bars an ideal choice in earthquake-prone regions, reducing the risk of catastrophic structural failures.

Furthermore, the durability of steel bars contributes significantly to the overall lifecycle cost of construction projects. According to a study conducted by the International Federation for Structural Concrete (fib), structures utilizing high-quality steel reinforcement can remain serviceable for over 100 years with minimal maintenance. This longevity not only ensures safety and reliability but also offers financial benefits over time, as maintenance and replacement costs are substantially lowered. With the increasing emphasis on sustainable building practices, these properties position steel bars as a favored material in contemporary construction methods, aligning with both economic and environmental goals.

In 2023, the steel bar industry is witnessing significant advancements in production methods and an evolving landscape of usage trends that cater to sustainability and efficiency. With the global construction market expected to reach USD 15 trillion by the end of the year, the demand for high-quality steel bars has never been higher.

According to recent industry reports, the production of eco-friendly steel is on the rise, with manufacturers increasingly turning to electric arc furnaces, which are known to reduce carbon emissions by up to 75% compared to traditional methods. This shift not only meets regulatory standards but also aligns with construction firms' growing commitment to sustainability.

A significant trend in steel bar usage is the increasing implementation of high-strength reinforcement bars, specifically in infrastructure projects. These bars offer enhanced mechanical properties, allowing for the construction of more resilient structures while reducing overall material consumption.

Data from a 2023 market analysis indicates that the sector is shifting towards utilizing corrosion-resistant steel bars, which can significantly prolong the lifespan of structures and minimize maintenance costs. Additionally, innovations in smart steel technology, which integrates sensors into the bars, are set to improve monitoring capabilities and structural health assessments in real time.

Tips: When selecting steel bars for your projects, prioritize those with certifications for sustainability and performance. Consider materials that can withstand environmental challenges specific to your location. Additionally, stay informed about local regulations regarding steel usage to ensure compliance and optimize your project's success.